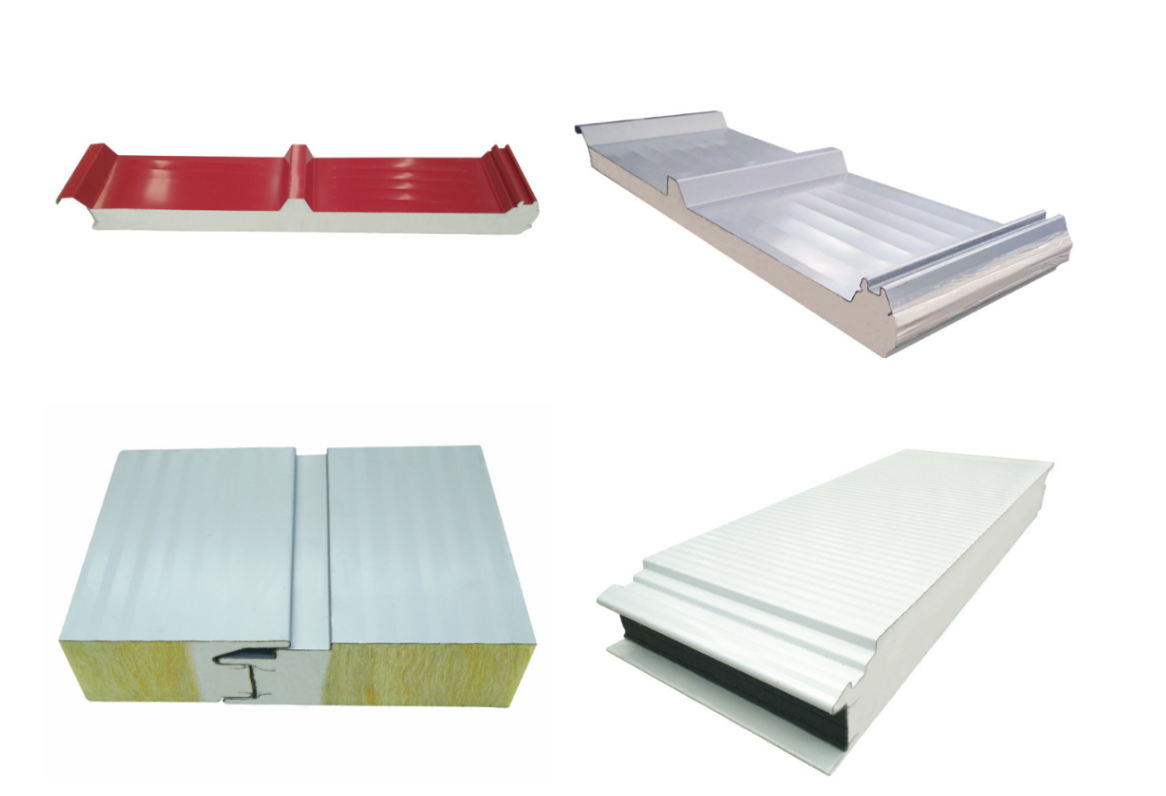

High Quality Sandwich Panel Easy Installation PU Sandwich Panel for Roof and Wall

COMPANY OVERVIEW

Growing Your Skills

Providing Best Talent Solution For

We Have More Than 16+ Years Practical Experience

Huacheng BoYuan Hebei Building Materials Technology Co.,Ltd is a comprehensive industrial company integrating research and development,manufacturing and sale as well as installation.

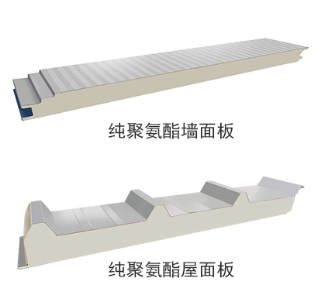

Polyurethane sandwich panel is a polyurethane thermal insulation sandwich panel for construction, also known as anti-leakage sandwich roof panel, polyurethane rigid foam insulation panel, polyurethane composite panel, PU panel, etc. It is a highly efficient and energy-saving building envelope material with a wide range of uses and great potential, and it is also a new type of energy-saving panel advocated and promoted by the Ministry of Construction.

wall and roof system

| Type | PU sandwich roof panel/polyurethane sandwich panel |

| Core | polyurethane |

| Density | 40-45kg/m3 |

| Surface material | color steel sheet/aluminum foil |

| Steel thickness | 0.3-0.8mm |

| Core thickness | 40/50/75/90/100/120/150/200mm |

| Length | 1-11.8m |

| Effective Width | 1000mm |

| Fire Rating | Great B |

| Color | Any Ral color |

| Wave | three waves or four waves (36mm、45mm) |

| Advantages | Lightweight/Fireproof/Waterproof/Easy Install/Insulation |

| Surface Appearance | seamless-wave/slitwidth-wave/concave-wave/Flat/Embossed/Other |

| Usage | It is suitable for the various wall and roofs referring to the large-size factory buildings, storage, exhibition halls, gymnasiums, freezing stores, purification workshops, etc. |

Definition of PU sandwich panels

Polyurethane Sandwich Panel also called PU Sandwich Panel, the top & bottom sheet of this panel is Galvanized & Pre-painted steel sheets,and core material is 5 components Polyurethane glue, it is formed by heating, foaming & laminating. Polyurethane is the best material for heat and sound insulation. It can reduce the heat transmission caused by difference in the internal and external temperature, and get to maximum efficiency of freezing and refrigeration systems. It is a new type of heat insulation material for lower construction cost.Panels are in multiple varieties and specifications to meet the need of various sites and projects.

Material instruction

1)Suface sheet:

Usually the surface sheet of PUR or PIR sandwich panels is PPGI or PPGL steel color coated sheets.PPGI is prepainted galvanized coated steel and PPGL is prepainted Al-Zn coated steel.For coating type,you could choose PE, PVDF, HDP, SMP,ect.Our strategic cooperation brands are Bluescope, Bao-steel, Shougang steel, Guanzhou steel, Yieh Phui steel,Xinyu steel,etc.

2)Polyurethane core material:Our polyurethane core material strategic cooperation brands are D·BASF, Huntsman, WANHUA, etc.

Features

Pre engineered for precision and simple construction.

Pre painted galvanized sheets.

Sandwich panels are extremely light weight

High structural rigidity and reliability.

Prefab Sandwich panel of various heights available

Heat, Sound and water insulated.

Fire and impact resistant.

Energy efficient.

Low energy consuming.