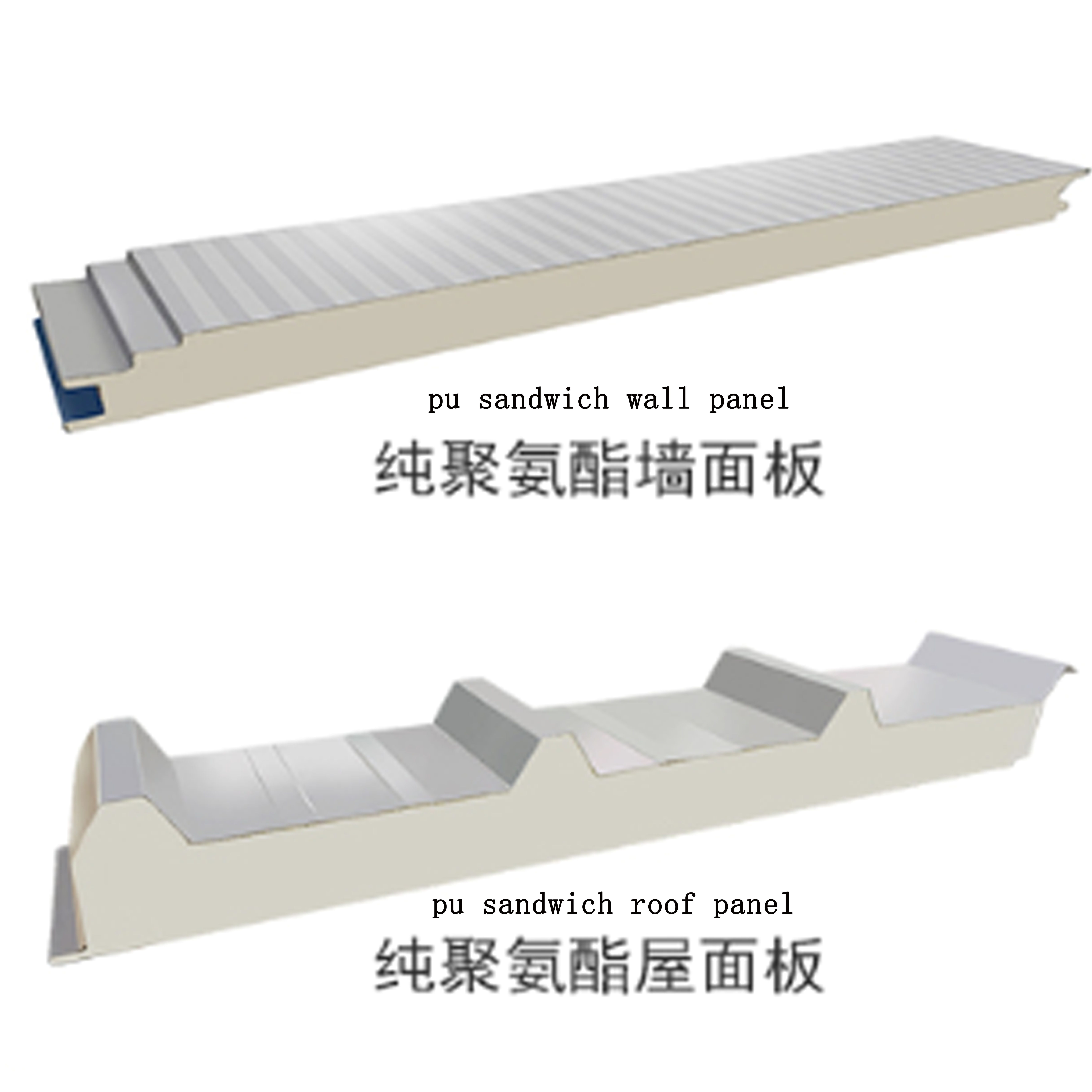

Photovoltaic roof panel PU/PUR/PIR Insulated Sandwich Roof Panel For Prefabricated House

Photovoltaic roof composite panel is a multifunctional roof system that integrates insulation, energy conservation, and solar energy utilization. Its roof crest can be directly connected to the buckle, without the need to penetrate the roof structure. It is suitable for industrial and commercial buildings with a roof inclination of 3%. The self-cleaning high-end panel reduces the amount of ash on the roof, keeping the building roof clean for a long time, providing a systematic solution for the utilization of solar energy on the roof.

Roof system

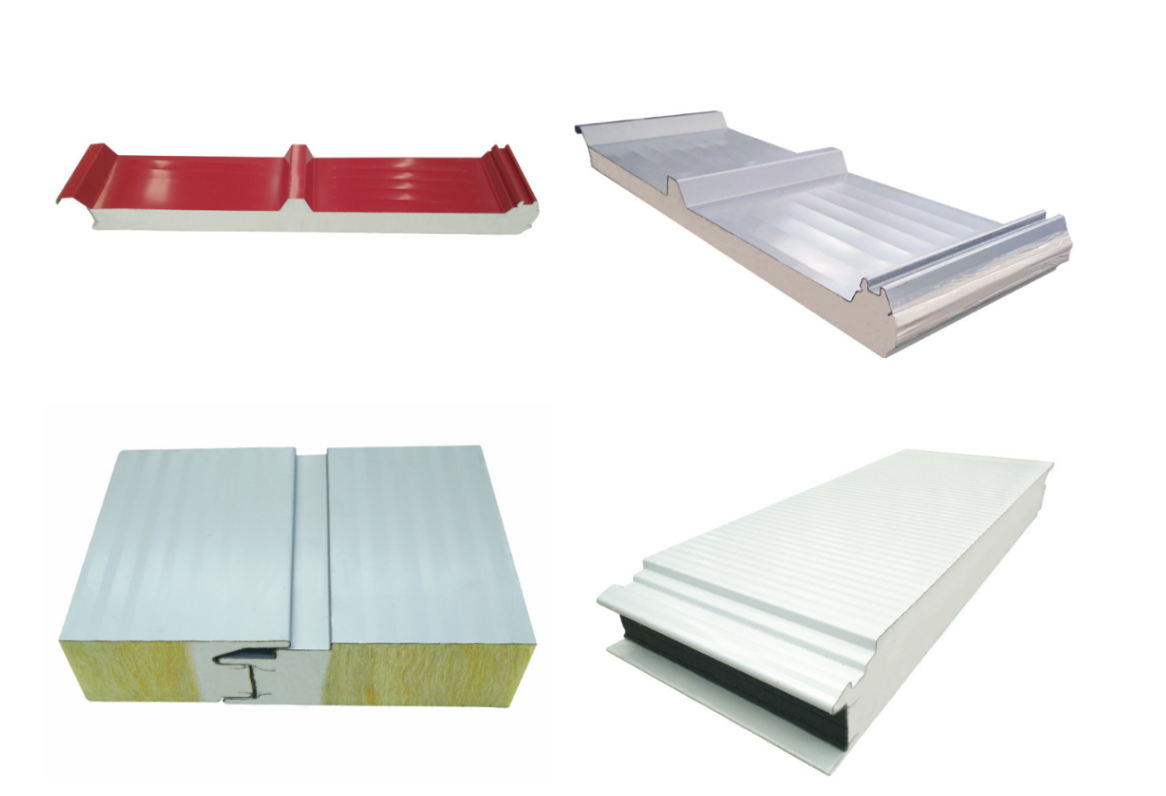

| Type | PU sandwich roof panel/polyurethane sandwich roof panel |

| Core | polyurethane/rockwool |

| Density | 40-45kg/m3;80-140kg/m3 |

| Surface material | color steel sheet/aluminum foil |

| Steel thickness | 0.3-0.8mm |

| Core thickness | 40/50/75/90/100/120/150/200mm |

| Length | 1-11.8m |

| Effective Width | 950mm,1000mm |

| Fire Rating | Great B |

| Color | Any Ral color |

| Wave | three waves or four waves (36mm、45mm) |

| Advantages | Lightweight/Fireproof/Waterproof/Easy Install/Insulation |

| Surface Appearance | seamless-wave/slitwidth-wave/concave-wave/Flat/Embossed/Other |

| Usage | It is suitable for the various roofs referring to the large-size factory buildings, storage, exhibition halls, gymnasiums, freezing stores, purification workshops, etc. |

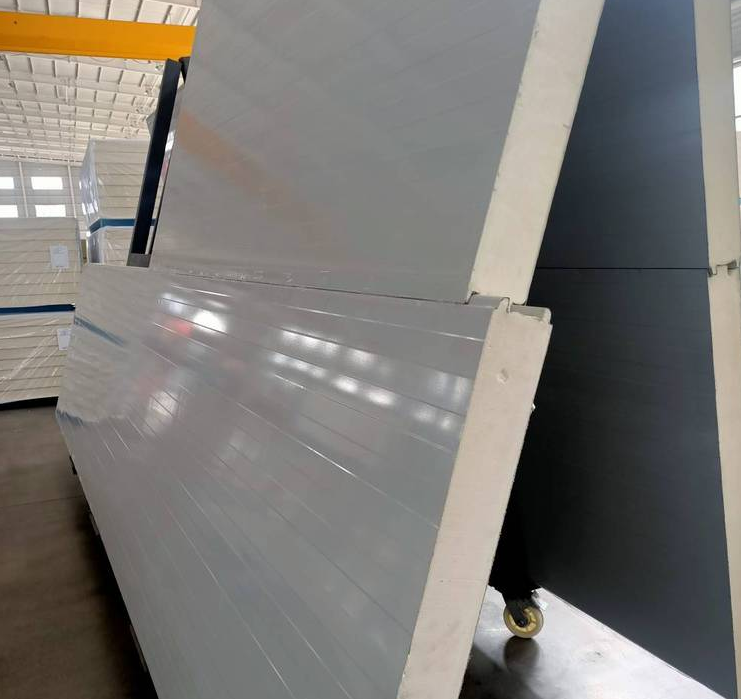

he roof panel of this system is specially designed for photovoltaic roofs, with high wave peaks improving the bearing capacity of the roof. It has the characteristics of large span, fast drainage, and convenient installation. The overlap adopts fluid mechanics design to ensure fast installation, airtightness, and 100% leak resistance. The roof panel is made of high-quality steel plate as the surface material. After continuous cold bending, it is injected with insulation and flame-retardant polyurethane liquid in the middle. After specific processing techniques such as high-pressure mixing, foaming, and curing, the core material and surface material are formed with strong compatibility. The board is produced using a standardized polyurethane continuous production line in the factory, and the product quality is stable.

Features

Pre engineered for precision and simple construction.

Pre painted galvanized sheets.

Sandwich panels are extremely light weight

High structural rigidity and reliability.

Prefab Sandwich panel of various heights available

Heat, Sound and water insulated.

Fire and impact resistant.

Energy efficient.

Low energy consuming.